The Greatest Guide To Injection Mold

Table of ContentsThe Of Injection MoldSome Known Details About Injection Mold The 30-Second Trick For Injection MoldNot known Details About Injection Mold Injection Mold for BeginnersRumored Buzz on Injection Mold

We can ensure you utilize the right materials and the ideal procedure that ideal fits your clinical tool demands.Prior to ejection from the mold, shot formed components are cooled down from making temperatures to make sure that they hold their form when ejected. During the part cooling action of the molding process, adjustments in pressure, speed and plastic thickness should be reduced to avoid problems. Couple of elements are a lot more crucial throughout this period than wall density.

Picking the correct wall thickness for your part can have radical impacts on the expense and also manufacturing speed of manufacturing. While there are no wall density constraints, the goal is normally to select the thinnest wall possible. Thinner wall surfaces make use of less product which lowers expense as well as take less time to cool down, reducing cycle time.

Injection Mold Can Be Fun For Everyone

Density transitions need to be made slowly, on the order of 3 to 1. This steady change stays clear of stress concentrations and abrupt air conditioning differences.

The Only Guide to Injection Mold

When it involves making your components, you have a significant decision to make. Should you make your parts making use of plastic injection molding or aluminum pass away spreading!.?.!? To assist you choose, let's check out the significant benefits and also negative aspects of each. The process of making a component is generally the exact same whether you are utilizing pass away casting or injection molding.

You after that liquify the product and make use of extreme pressure to infuse it right into the die/mold. There are some variants in strategy, the significant difference between die spreading as well as shot molding is that die casting uses some kind of steel, frequently a light weight aluminum alloy, as the raw product, while injection molding utilizes plastic or polymers.

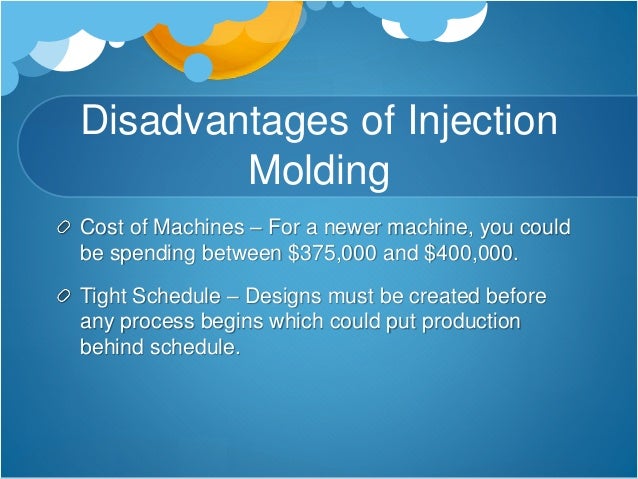

Production is quicker due to much more flexibility in the molding process Plastic Shot mold and mildews can suit different plastic or polymer materials Fillers can be utilized in plastic mold and mildews to raise strength Effective process with very exact finishes Reliable procedure with a high degree of precision No demand for secondary procedures Complex designs can be extra quickly cast Generates higher-quality products with much better resistance that will last longer So why would certainly you choose injection molding over die casting? If you are looking to generate a great deal of parts really cheaply, shot molding could be the way to go, as websites labor as well as material prices are fairly light, although it is important to maintain in mind that the expense of the plastic injection molding makers themselves and any type of second devices can be fairly expensive.

Rumored Buzz on Injection Mold

Also if you are creating easier parts, many individuals choose the apparent feeling of durability and high quality you enter a solid steel component over a plastic component. When you have actually decided that light weight aluminum pass away casting is the means to go with all your component manufacture requires, the next step is to speak to Premier Engineered Products.

We are a family-owned, U.S.-based business that does all of our die spreading in our advanced die casting plant and also have made top notch parts for industries ranging from guns to telecommunications to clinical devices as well as extra. Firms that understand pass away casting telephone call Premier Engineered Products. At Premier Engineered Products, we are dedicated to aiding you provide a far better item to your clients by using you fantastic solution and excellent high quality whenever you put an order with us.

To figure out exactly how we can put our modern metalworking devices as well as knowledge to work for you now, just call learn the facts here now us online today.

Injection Mold for Beginners

At Abtec Inc., we're honored to offer custom-made mold making services, assisting customers bring their product visions to life. Flexible and also reliable, plastic injection molding is utilized to create a massive series of Home Page day-to-day products. One of the most prominent approaches for standardizing plastic components, this strategy continues to increase in appeal throughout diverse sectors as well as applications.

Considering that durations between cycles can be as brief as 15 secs, more parts can be made meaning countless precision parts can be produced per hour, depending on the details mold and mildew. This high production output rate assists companies enhance income and also revenue margins. Custom plastic injection molding enables terrific style flexibility.

005 inch. Having a full understanding of clients' requirements is crucial for ensuring proper product type and function. With years of market experience and also a devotion to close client cooperation, our group is able to figure out the optimal layout and also product for consumers' projects, and can start job promptly on models (Injection Mold).

The Main Principles Of Injection Mold

Material selection is a crucial step in the production process, and have to be based on the intended toughness of the end item. Other key variables to bear in mind include look attributes, such as color as well as coating, as well as any kind of applicable governing requirements. Loads of material alternatives are offered to satisfy particular application demands.